The Consistency Experts

-

Consistency Experts for the Pulp & Paper industry!

>> more info

Consistency Experts for the Pulp & Paper industry!

>> more info

-

Tighter consistency - and made right here in the USA. >> more info

Tighter consistency - and made right here in the USA. >> more info

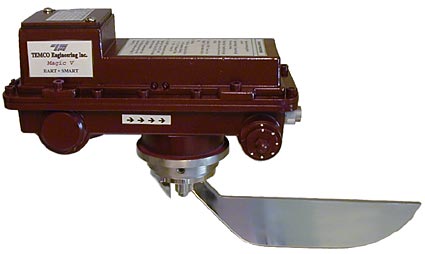

MAGIC V

TECO is proud to introduce the Magic V, a Smart, fixed blade meter with a faster response and improved reliability.

- Pre-calibrated for ten different types of stock to match any furnish.

- Hydraulic dampener for fast consistency response.

- Mechanical Zero that enables recovery from "HITS" to sensor.

- Span is ranged using the standard hand held communicator.

- Operating parameters only assessable to authorized personnel.

- Mounts on existing installations. No pipeline changes are necessary.

- HART compatible meter can be recalibrated from control room.

- Loop Powered.

The Magic technology is more responsive to rapid changes in consistency. This enables the controller to "see" process upsets and hold consistency closer to set point. By reducing consistency variations in the feed stock to the Paper Machine, paper quality will be improved while using less fiber.

TECO's Magic V is a loop powered fixed blade consistency transmitter. The transmitter measures consistency by sensing the "shear force" on a static blade in the stock stream. The size and shape of the blade is designed to compensate for small flow variations. Consult TEMCO Engineering about selecting the proper blade for each application.

Magic V's SMART feature has ten response curves stored in memory to match the nonlinear pulp response curves. This gives higher accuracy than traditional linear response curves because it adjusts for higher sensitivity at low consistency and lower sensitivity at higher consistency.

Magic V's HART features uses digitally set upper and lower range values. With a HART compatible device, you can program or read the loop's current output and consistency value anywhere the 4ma to 20ma wires run; from the control room to the transmitter.

HOW DOES Magic V WORK?

The blade type consistency meter operates on a "shear force" principle. As stock moves through the pipe it encounters the leading edge of the consistency meters sensor blade. The amount and properties of the stock, combined with the flow rate result in a "shear force" against the sensor. This force causes the sensor blade to pivot; the amount of movement is proportional to the force needed to separate "shear" the fibers. The sensor blade is connected to a differential capacitor system. This non-contact device measures the movement and produces a variable voltage that is proportional to consistency. Thus "shear force" is converted into a voltage. This voltage is fed into a "SMART" module. The module converts the voltage into a 4-20 ma signal. By utilizing a look up table, the nonlinear consistency sensor voltage is converted to a linear 4-20ma output. The module communicates via HART protocol on the 4-20 ma signal wires. Span, upper & lower range values and other variables can be adjusted using a standard hand held communicator.

The "shear force" sensor is designed to compensate for flow variations. This is accomplished by the size and shape of the sensor blade. Proper operation depends on selecting the correct sensor for a known flow and stock parameters. When a fluctuating process causes these parameters to exceed the sensors compensating range, the rotating style of consistency meter is recommended. The rotating sensor [MAGIC II or III] creates a constant flow across the sensor. This enables the rotating meter to provide a higher degree of repeatability and accuracy in these applications.

Valmet® is a registered Trademark. TECO has no affiliation with this OEM.

Technical Specifications

MAGIC V SMART + HART

2-Wire, All Electronic Loop Powered Consistency Transmitter

- Power Requirements - 2-wire, 24-30 volts DC.

- Output Signal - 4-20 ma into 350 ohm max. load @ 24 volts,1300 ohms @ 30 volts.

- Output Dampening - Silicon oil dampener plus digital electronic filtering, 0.5 to 100 seconds(3.0 sec. factory setting)

- Pulp Curves - (10) calibration curves, 1.0 to 7.0% installed in transmitter.

- Consistency Range adjustments made in % consistency from any HART Protocol Adjustment device such as a Meriam™, Rosemount™ or SMAR™ Communicator.

- Consistency Sensing - Flow Compensated Stationary Blades.

Our Products

MAGIC II

Rotating Sensing Disk Meter with faster response and improved reliability. Pre-Calibrated with SMART + HART.

MAGIC III-16

Rotating Sensing Disk, mounted in a side chamber with Pre-Calibration and SMART + HART. Motor 440 volts 3 phase or 117VAC.

MAGIC V

Fixed blade consistency meter with 6 blades for different furnishes and ranges. Pre-Calibrated with SMART + HART.