The Consistency Experts

-

Consistency Experts for the Pulp & Paper industry!

>> more info

Consistency Experts for the Pulp & Paper industry!

>> more info

-

Tighter consistency - and made right here in the USA. >> more info

Tighter consistency - and made right here in the USA. >> more info

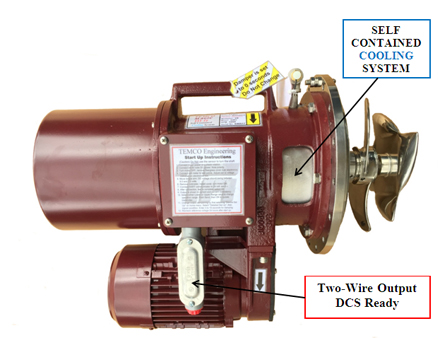

MAGIC III-16

TECO is proud to introduce the Magic III, a SMART, Rotating Sensing Disk.

- Pre-Calibrated for (10) different types of stock to match any furnish.

- Self contained Bellows Cooling System eliminated the need for seal water.

- Uses existing measuring chamber and sensor.

- HART compatible meter can be recalibrated from control room.

- High torque belt drive system is standard.

- Loop Powered, two-wire electronics.

- Long Life Electronic Coupling Option for 2016.

The Magic III measures consistency by drawing a continuous flow of stock past the sensor at a constant velocity. A motor driven propeller provides the steady flow which makes the torque signal insensitive to flow change in the pipe. The consistency sensor is “Outside the Pipe” in a weld on bulb.

HOW DOES Magic III WORK?

TECO's Magic III transmitter measures consistency by sensing the change in shear force with the rotating sensor. A non-contact Magnetic Inductive Coupling. (Magic) ThermaCoil measures these torque variations. This system is faster responding than a feed back coil system..

Magic III's SMART feature uses ten response curves stored in memory to match the nonlinear pulp response curves. This gives higher accuracy than traditional linear response curves because it adjusts for higher sensitivity at low consistency and lower sensitivity at higher consistency.

Magic III's HART feature uses digitally set upper and lower range values. With any HART compatible device, you can recalibrate Magic III or read the loop's current output and consistency value anywhere the 4ma to 20ma wires run; from the control room to the transmitter.

Magic III measures consistency by sensing changes in torque, and converting it into a 4ma to 20ma reading like any rotary consistency transmitter. The degree of torque applied to the rotary disk affects the distance (air gap) between the torque arm and the ThermaCoil. A change in distance between the torque arm and the ThermaCoil changes the inductance. This change in inductance affects the frequency of the oscillator circuit which affects the amount of voltage drop across a coil / capacitance circuit. A two wire transmitter chip with HART protocol converts this voltage change to a 4ma to 20ma current signal which is independent of load or supply voltage. A digital filter is built in for signal damping if necessary. A thermistor is used for temperature compensation.

Technical Specifications

MAGIC III SMART + HART

- Power Requirements: 2-wire, 24-29 volts DC, minimum 250 ohm loop resistance. Motor 3 phase 440-480 VAC @ 60 Hz. Optional 117VAC Single Phase @60Hz available

- Output Signal: 4-20 mA (limited to 23 mA) into 350 ohm max. load @ 24 volts,700 ohms @ 29 volts.

- Output Dampening: Digital 1.5 to 100 seconds( 5 sec. factory setting )

- Output Jacks: 4 to 20 ma. Equal Upper & Lower Range

- Pulp Curves: TEN Calibration curve, 1 to 7% installed in transmitter. Curves selection via HART. Span (Min. 1% Max. 5% )

- Sensitivity: Better than +/- 0.025% as % consistency

- Repeatability: +/- 0.3 % full scale (constant operating conditions)

- Operating Conditions: Max. stock Temp. 140 °F - Ambient Temp.140°F. Max. Process Pressure @ 257°F

- Materials: Wetted Parts : 316 S/S - Housing : Aluminum

- Seal Cooling: Self-Contained cooling using heat transfer fluid. No external water required.

- Consistency Range adjustments made in % consistency from any HART Protocol Adjustment device such as a Meriam™, Rosemount™ or SMAR™ Communicator.

- Consistency Sensing: Standard Motor Driven Disc and Shaft to Generate Torque from Consistency changes.

- Torque Sensing: Non-Contact Inductive coupling with Stationery Pick-Up Coil; approximately .030 in Air Gap.

- MAGIC III Upgrade: Can be installed on any existing pneumatic or electronic BTG® transmitter.

Our Products

MAGIC II

Rotating Sensing Disk Meter with faster response and improved reliability. Pre-Calibrated with SMART + HART.

MAGIC III-16

Rotating Sensing Disk, mounted in a side chamber with Pre-Calibration and SMART + HART. Motor 440 volts 3 phase or 117VAC.

MAGIC V

Fixed blade consistency meter with 6 blades for different furnishes and ranges. Pre-Calibrated with SMART + HART.